- Metal

- Wood

- Plastics

- Rubber

- More

Metal

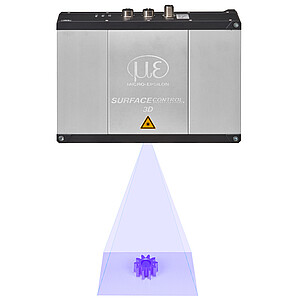

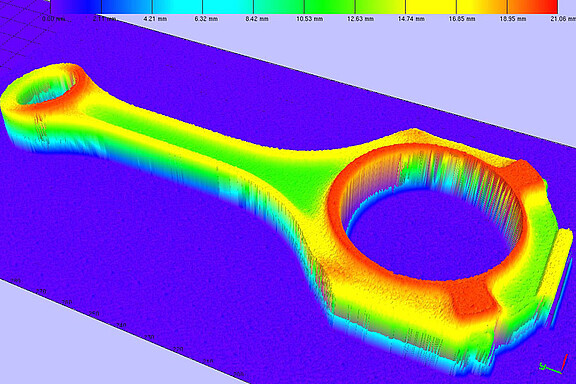

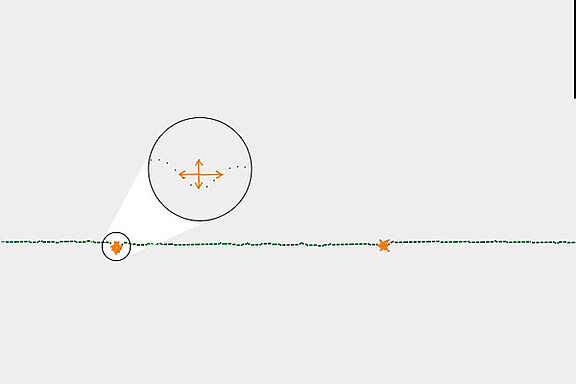

Linear 3D capturing of parts

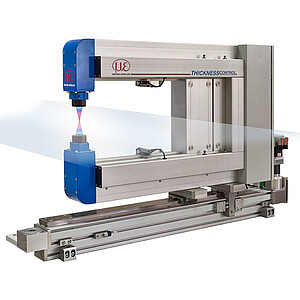

- Modular system by the company Mabotic

- Quick and easy digitalization

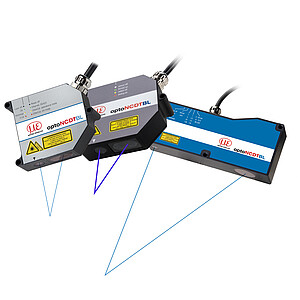

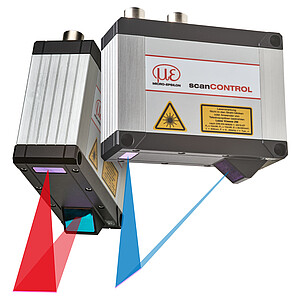

- No deformation of single profiles by means of the global shutter from the scanCONTROL profile scanner

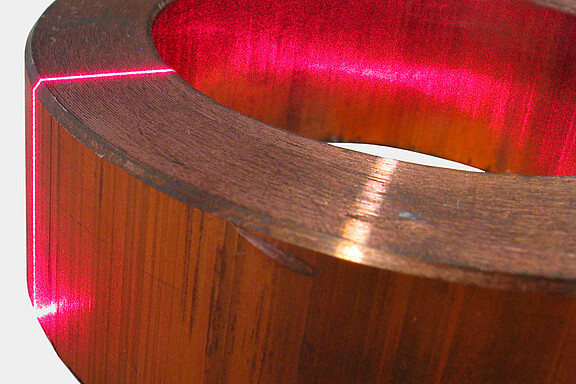

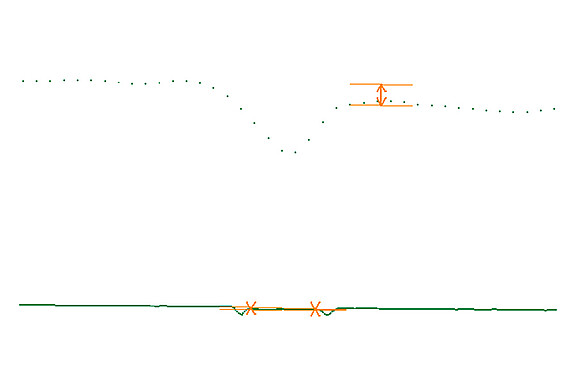

Chamfers on copper rings

- Material is corroded and has changes in the degree of gloss

- Complete measurement takes less than 1 second

- Width of the chamfer is at 0.8 mm

- Additionaly the angle of the chamfer is being checked

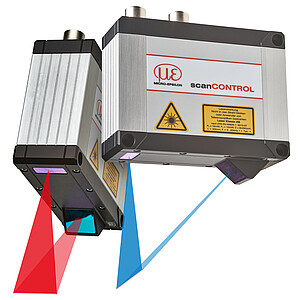

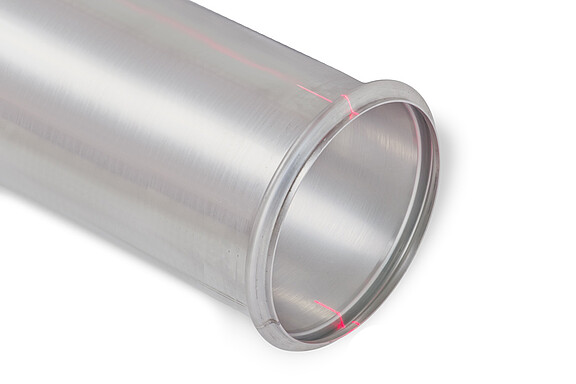

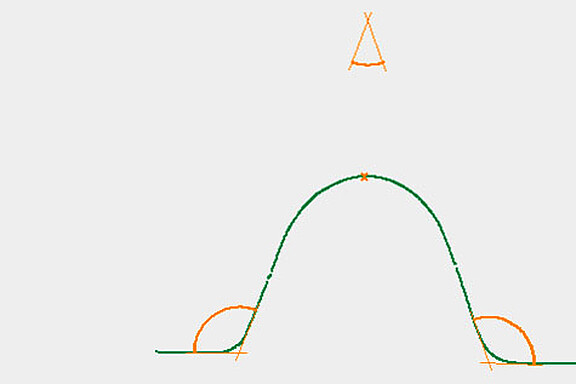

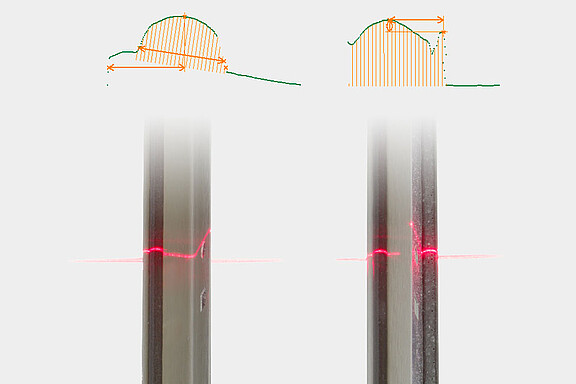

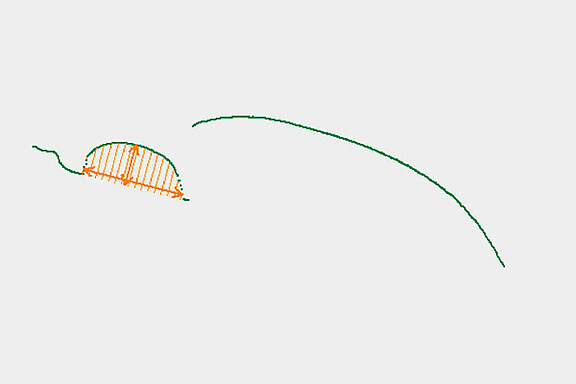

Outline measurement on pipe ends

- Using a scanner for each end

- Shiny surface

- Partially steep edges

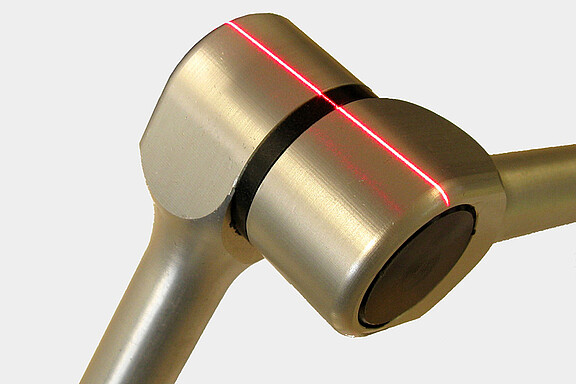

Measurement of concentricity on joints

- Connection of two parts with a metal slide bearing

- Circular control (180°) and step measurements

- Derivated from that determination of the concentricity of the three elements

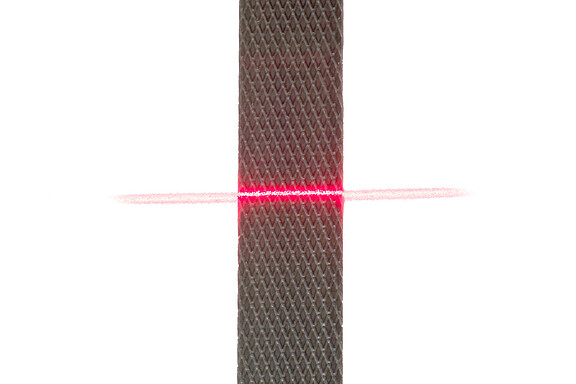

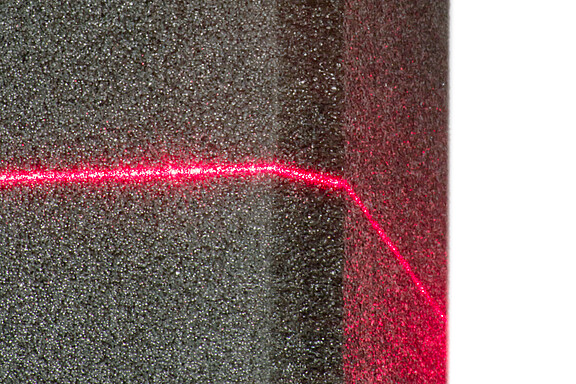

Velvet control

- Position of the velvet

- Height of the velvet

- Defects/Tipping of the velvet

- 250 velvets/min

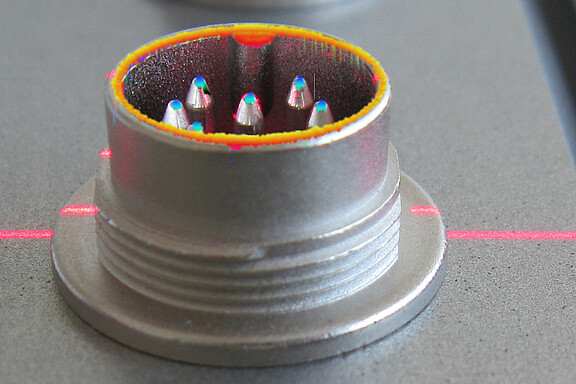

Pin control

- Position of pins

- height of pins

- Number of pins and defects

- 187 pins / min

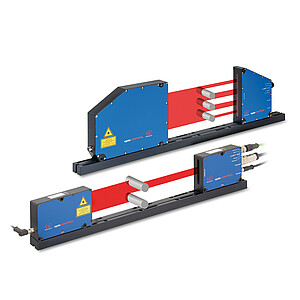

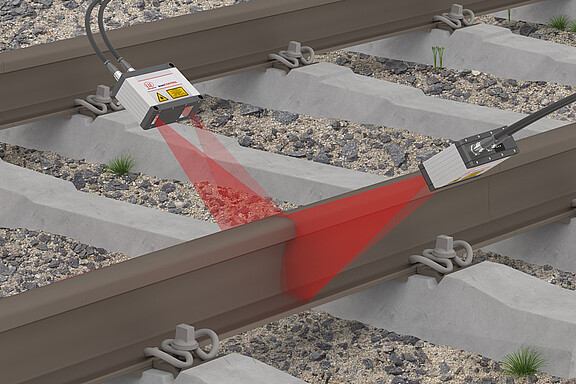

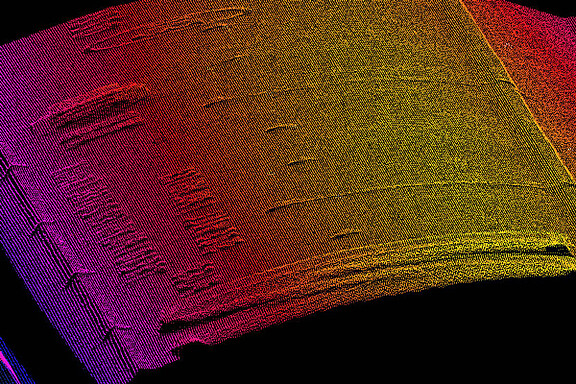

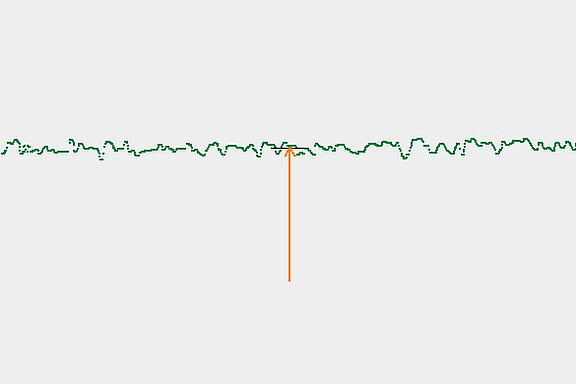

Railway tracks

- 2 scanners per rail

- 50mW laser for highspeed measurement on rails (partially shiny or dark surfaces)

- Ambient temperature from -20 to +80 °C (Cooling and heating by a customer system)

- Detection of defects on the rails during the overrun

- Evaluation software by customer

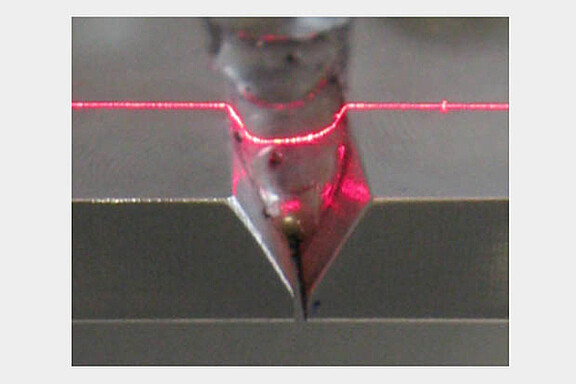

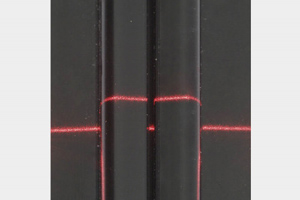

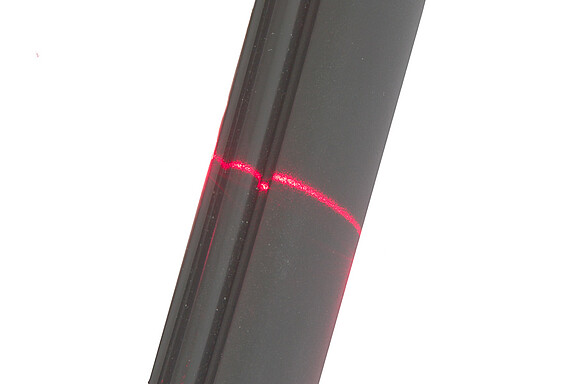

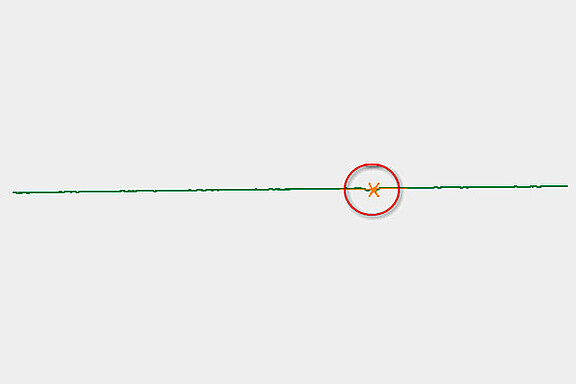

Tracking of a welding seam on pipelines

- Measuring the position of the welding seam

- Detection of interruptions in the welding seam

- Measuring speed 30m/min

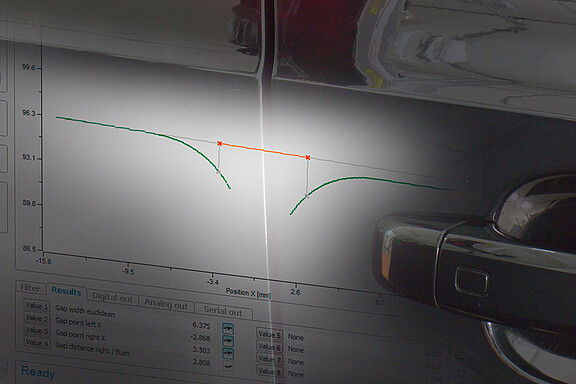

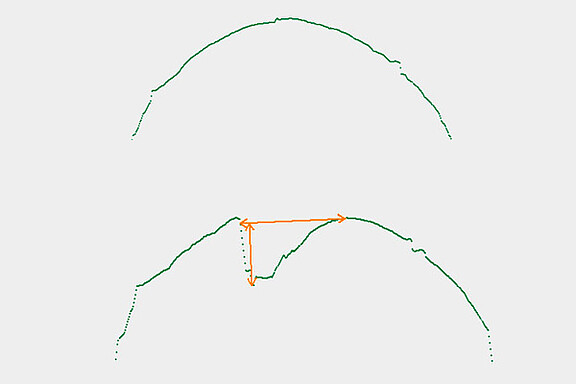

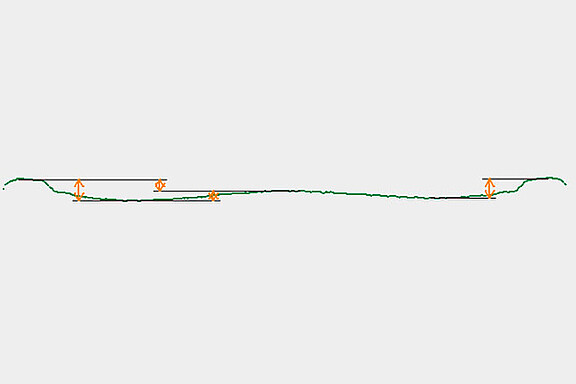

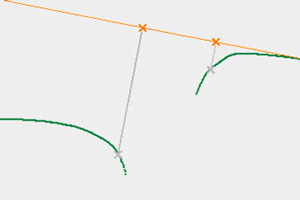

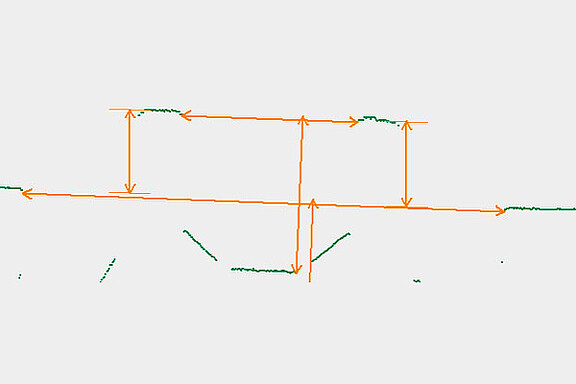

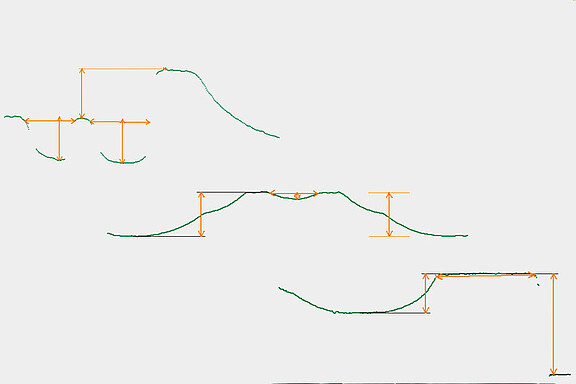

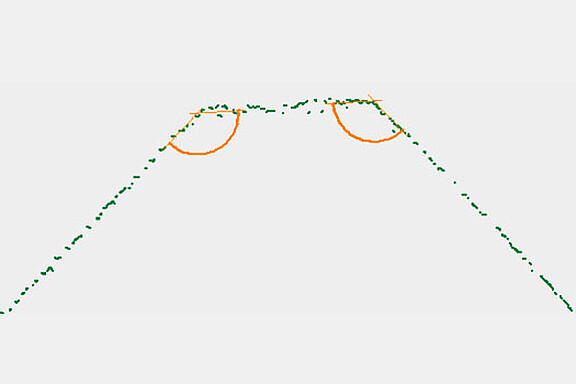

Gap measurement on car bodies

- Gap width

- Alignment of the car body panels

- Special algorithms are used to enable measurements on any car color

- Fully automated using in production lines of various car manufacturers

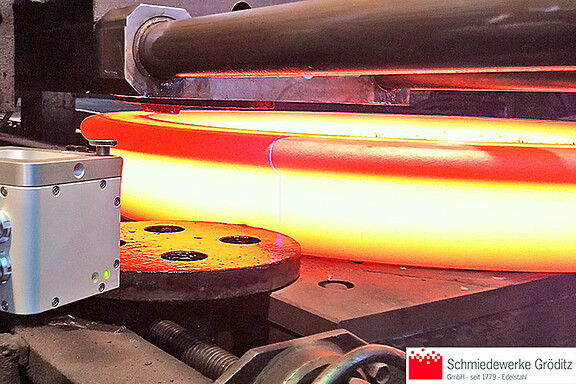

Measurement of forged steel wheel tyres

- Inline measurement right after the forging process at the company Schmiedewerk Gröditz GmbH

- Temperature 1200°C

- Different dimensions are checked

- Cooling housing by customer

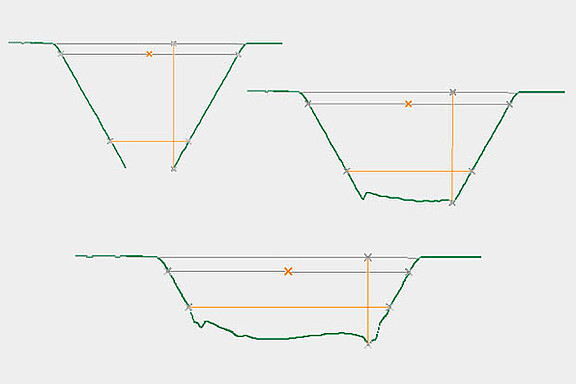

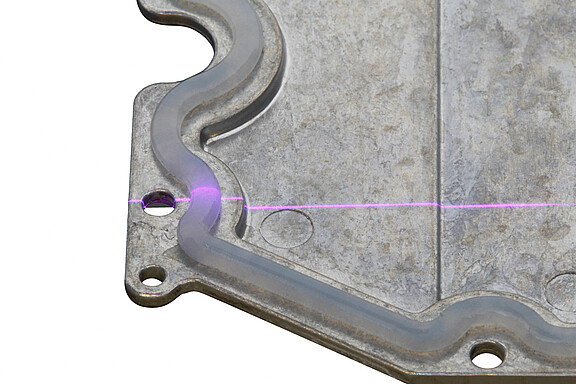

V-profile measurement

- Building up in several process steps

- Continous monitoring of gap width and depth

- Tracking of the welding head based on the position of the gap center

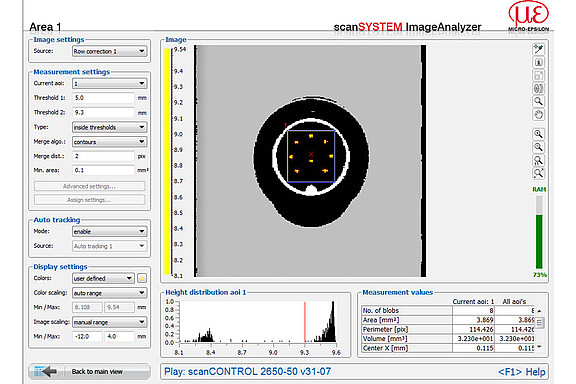

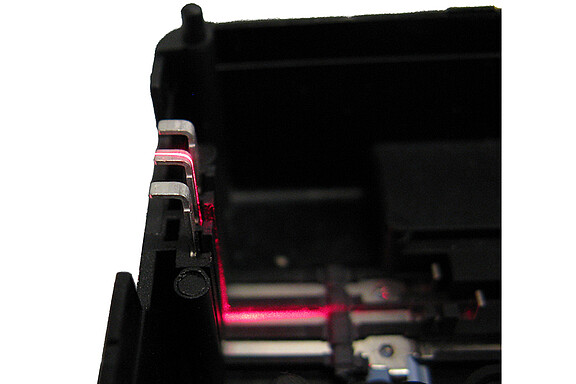

Angle measurement on pin contacts

- Short cycle times, fast measurements

- Several pin contacts are measured in every housing

- Measurement of any single contact

Wood

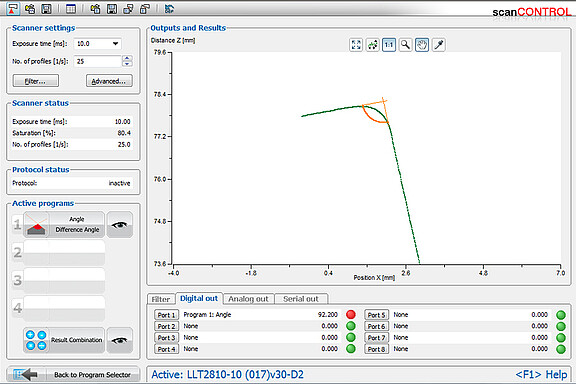

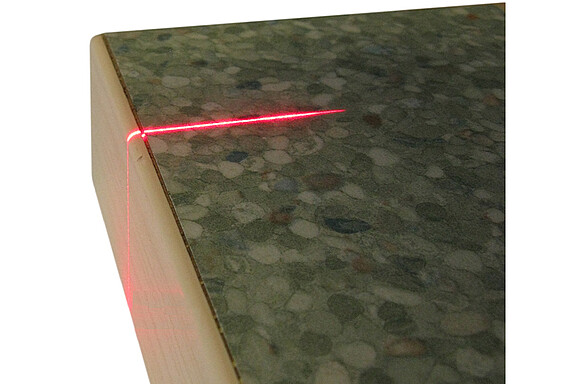

Defect detection on counter tops

- Glueing of the end strip is partially not flush

- Detection of grooves between the two parts shows defects

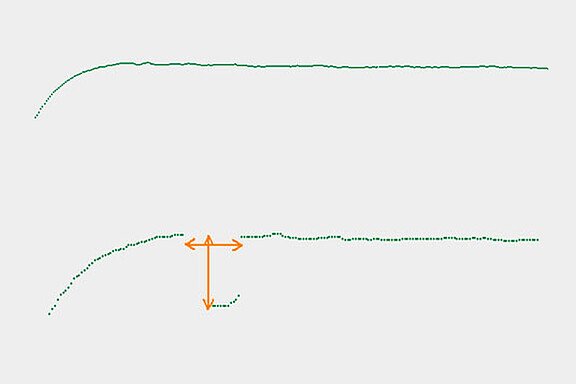

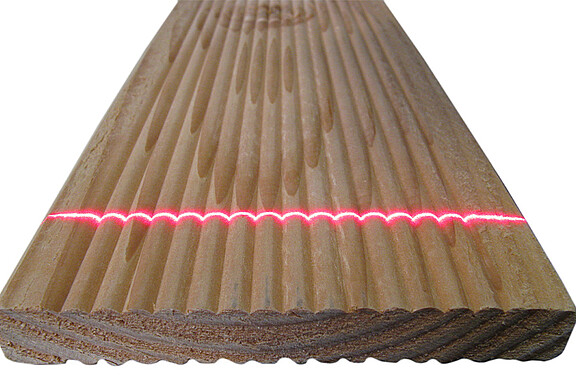

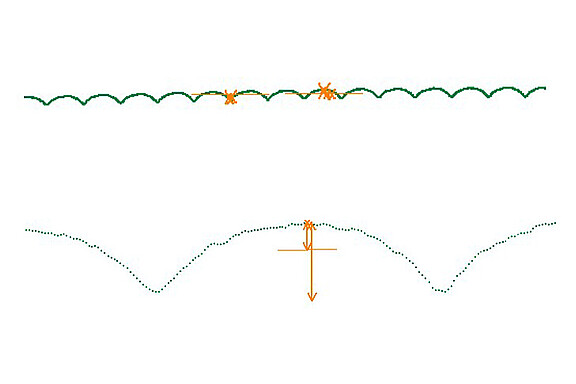

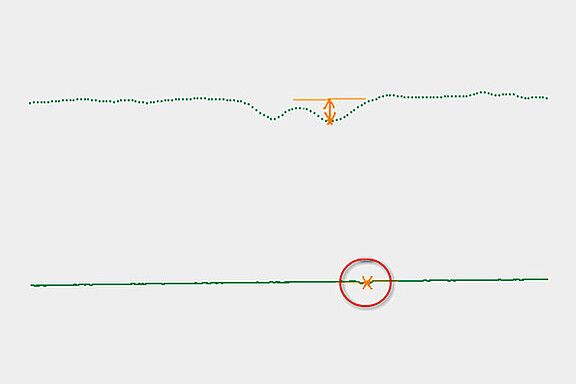

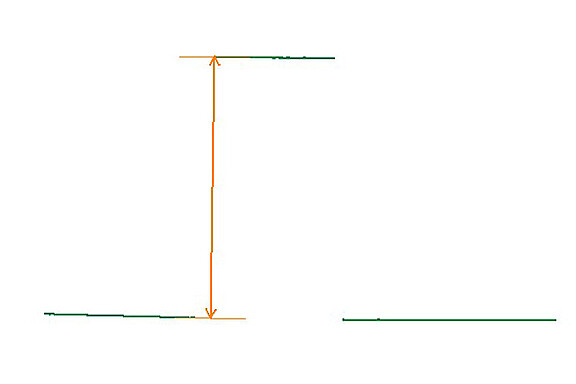

Control of the contour on timber floor board

- Difference in brightness due to the texture

- The height difference between the lowest and highest point is analysed

- Measuring on a width of 130 mm

- Speed: 10 m/s

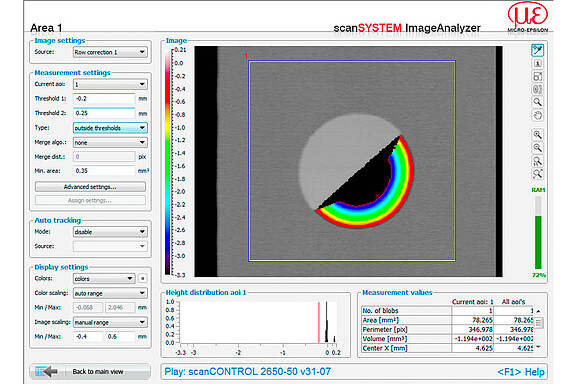

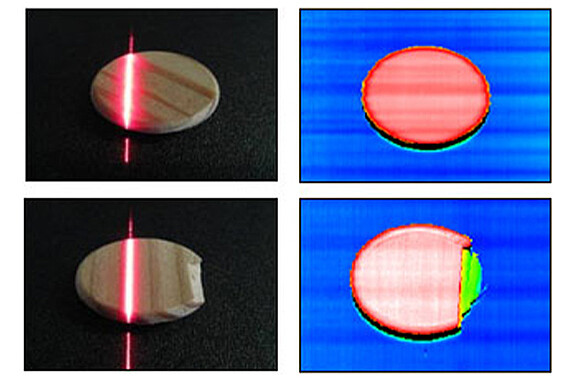

Control of wooden plugs

- Analysis of the reflection intensity

- Analysis of the elevation profile

- scanSYSTEM ImageAnalyser

- Checking: Roundness, resin embedding, breakouts, tilt, ….

- OK/NOK data is transferred to a PLC via RS422

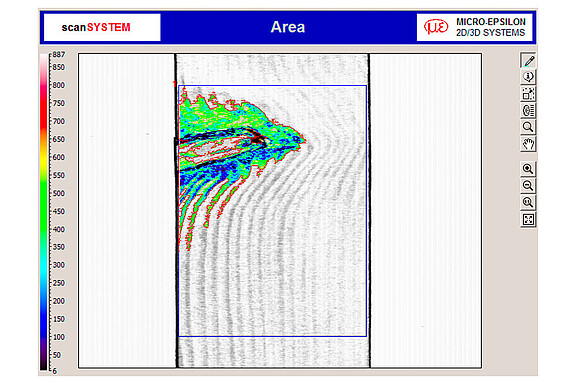

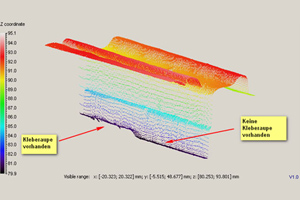

Control of wooden planks on knotholes

- Checking for defects on the surface

- Quantity, size and shape of the defects is displayed

- Calculation with the measurement values and transfer to the control system

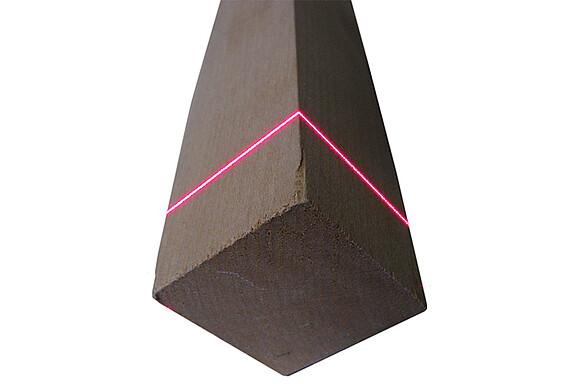

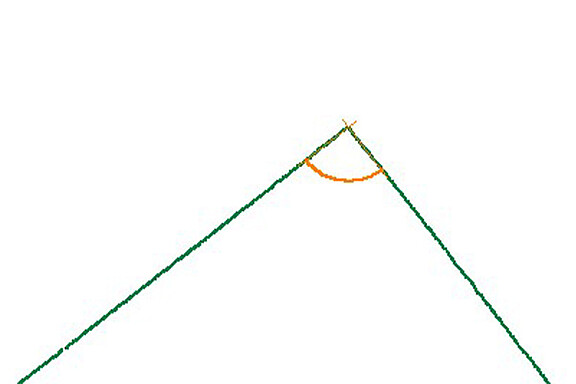

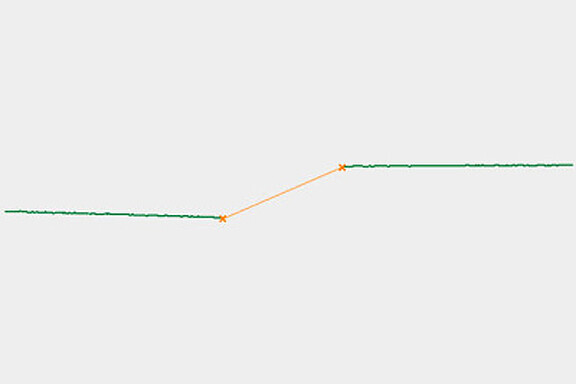

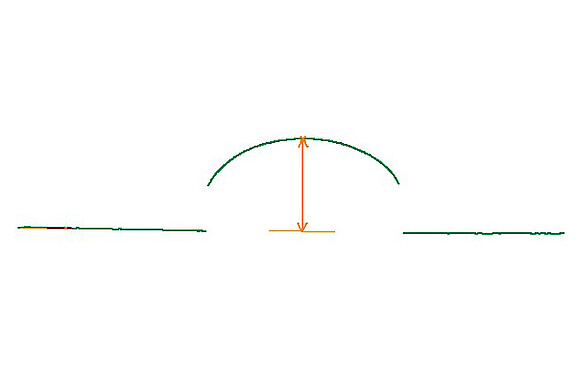

Rectangularity of wooden balks

- A continuous incoming goods inspection is realised at the plant of the customer

- The good and constant quality of the final product is assured

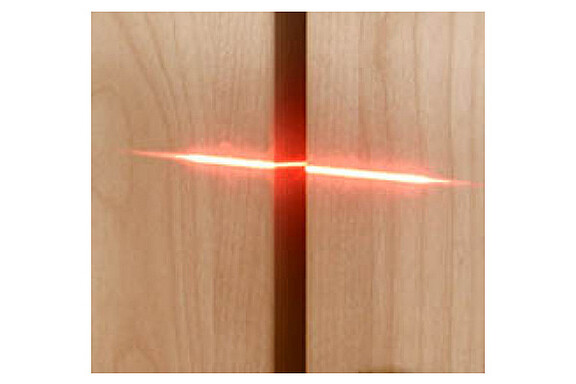

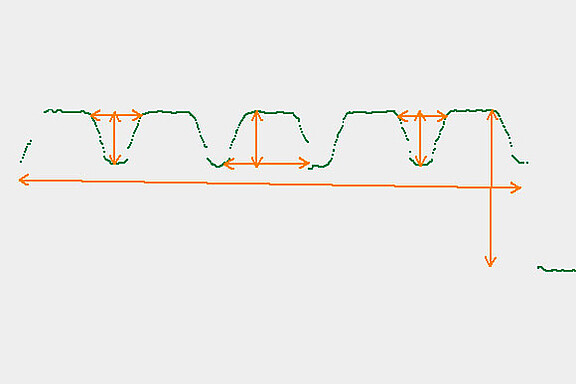

Control of springs on parquet planks

- Target material: wood

- Detection of the upper edge

- Detection of the notch and monitoring of the edges

Defects on the surface of parquet planks

- Find the minimum and maximum point of the surface

- If a critical value is reached a defect will be detected

- This shows sinks or inclusions

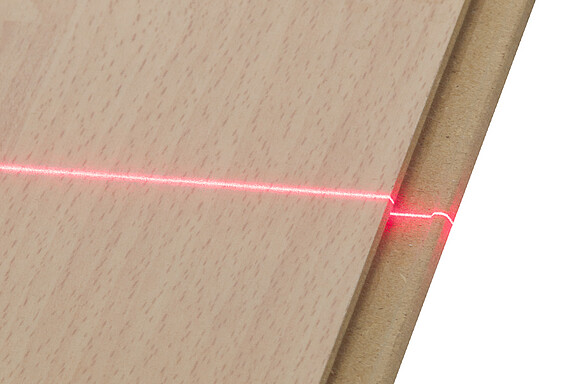

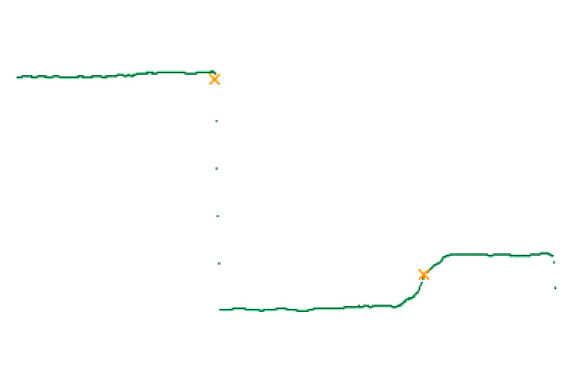

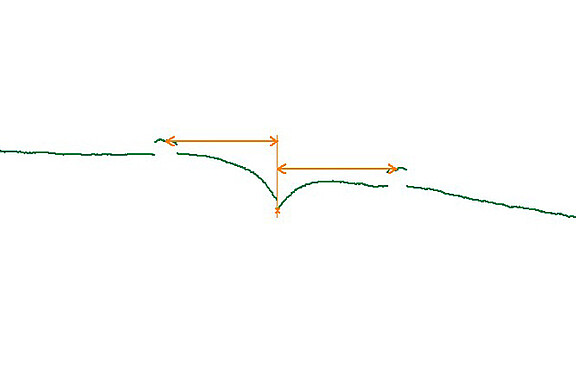

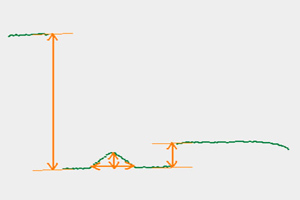

Gap measurement on wood

- Target material: wood

- Control of the gap width

- Control of the alignment

Plastics

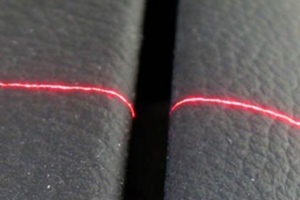

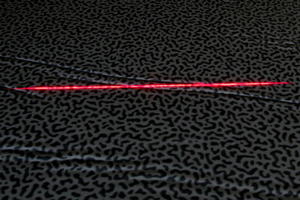

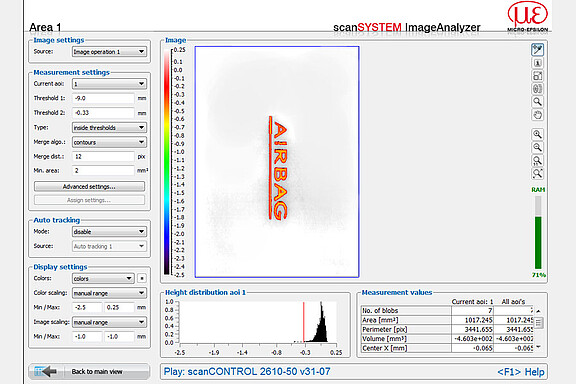

Position of decorative stitching on airbags

- Constant run and completeness are checked

- Defects would be seen by the car buyer directly

- Promotion for the brand image by means of visible quality

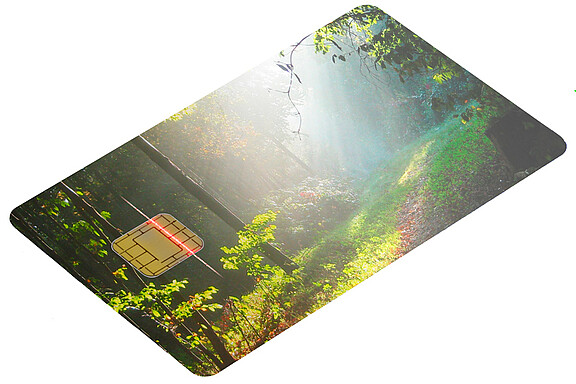

Measurement of the chip thickness in cards

- Control of the presence

- Measurement of the chip thickness relatively to the card‘s surface

- Partially shiny surfaces

- Varying printing colours

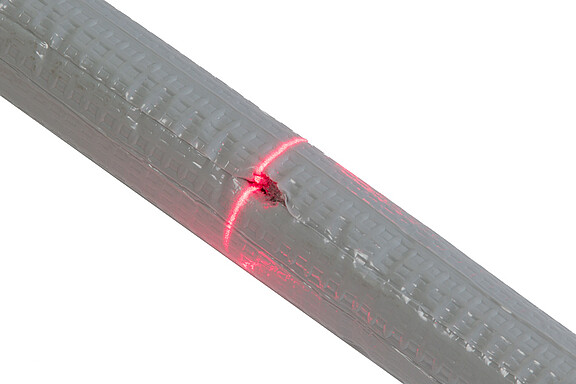

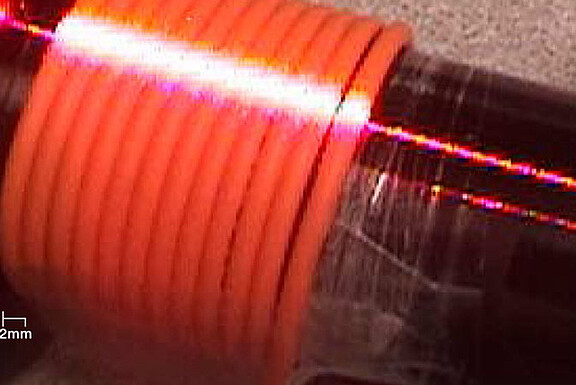

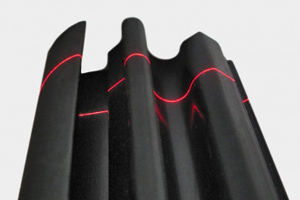

Detection of defects on pipe insulations

- Detection by searching for grooves

- Also small defects can be detected

- Different surface reflection on the outer and inner material

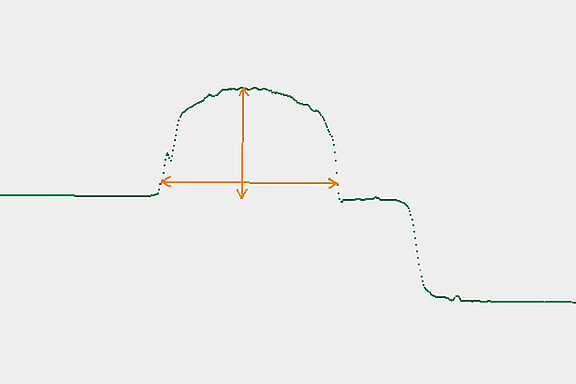

Adhesive beads on geometry

- Presence of the adhesive bead

- height and width of the adhesive bead

- Internal and external height of the object

Adhesive bead control on stove borderings

- Using two scanners

- Detection of presence

- Control of width and height

Dimension control on packaging tapes

- Measurement of width

- Measurement of thickness

- Highspeed measurement

Position control on a lid‘s grip

- The lid‘s grip is turned around and when the seam is detected the rotation stopps

Process control in the production of plastic cups

- Control of several dimensions

- Detection of unacceptable bulges

- These bulges are based on problems during the extrusion

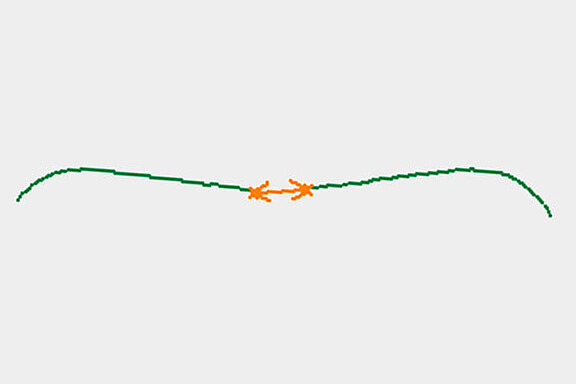

Gap measurement in vehicle interiors

- Measurement of the gap width on various materials like rubber, metal and plastic

- Alignment control between different parts of the interior

Gap measurement on plastic profiles

- Measurement on high speed

- Black shiny surface

Detection of flash on injection molding parts

- Mass production

- Flash is a visual defect

- Flash provides an indication on changes in the process parameters

Automated machinery winding fiber cable

- Fiber cables are damaged when they are winded inaccurately

- Obvious reduction of the loss by using a winding machine that is checking the process contactless with a laser scanner

- Complete turnkey solution by a system integrator

- Winding speed up to 5 m/s

Rubber

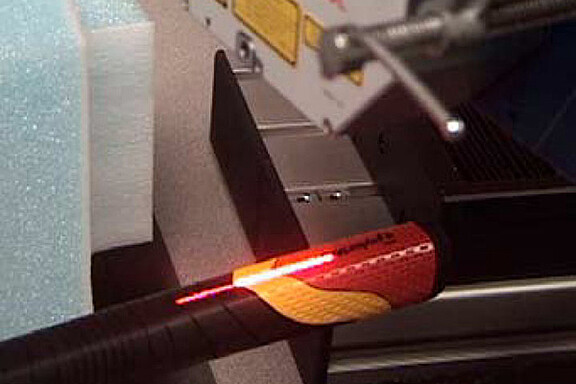

Position of the rubber grip on golf clubs

- High resolution and fast measurement

- Final customers make high demands on feel and look of the golf clubs

- Non-contact measurements treat the material with care

- Complete turnkey measurement system by a system integrator

Rubber profile control

- height and width of the inner shape

- Angle between the two flans

- height of the outer shape

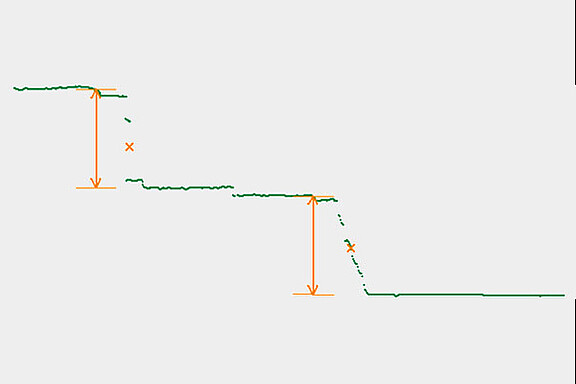

Position and thickness of layers on a roll

- Target material: black rubber

- Calculation of step heights

- Determination of edge positions

Sealing beads in vehicle interiors

- Detection of presence

- Detection of defects like changes in width or height

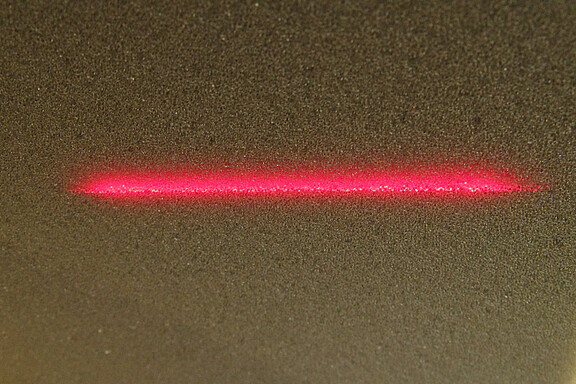

Tire control

- Tire control system developed by ME-Inspection

- 50mW-laser for Highspeed-measurements on black rubber (high light absorbing surface)

- Profile and concentricity control

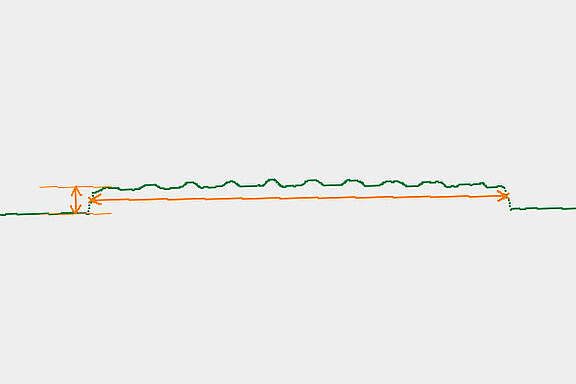

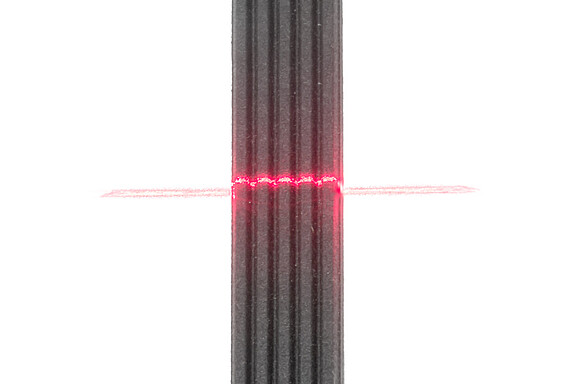

Measurement of rubber profiles

- Control of dimensional accuracy

- Mat black surface

- High profile frequency

Roll measurement

- height of the roll compared to the position of the stoppers

- Width of the tires

- Width of the stoppers

- Measurement during tire rotation

More

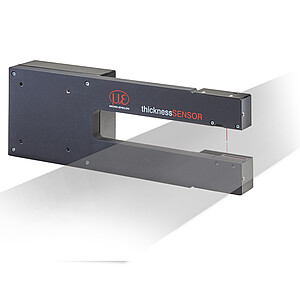

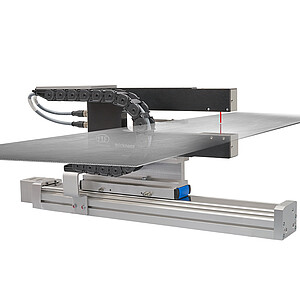

Thickness measurement on foam material

- Point measurement is not possible because of the rough surface

- Averaging of the profile to detect the thickness

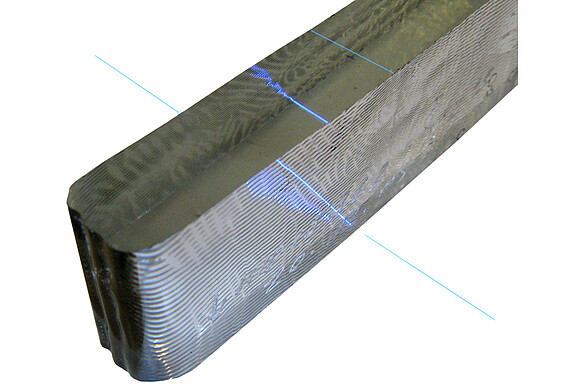

Quality assurance for railway sleepers

- Single profiles are matched to build a 3D model

- Control of all specific dimensions by customer owned software

- The target is to minimize the rejects in the production by means of realtime process adaptions

- Aggressive dust and dirt

- Great variations in temperature

Height measurement on wine gums

- Quality control

- Control of different measures, especially height

- Tests in laboratory

- Sample check

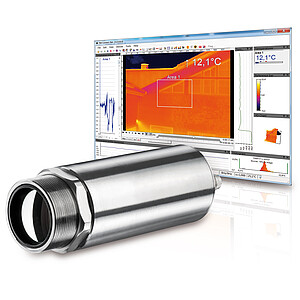

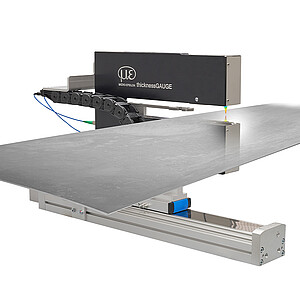

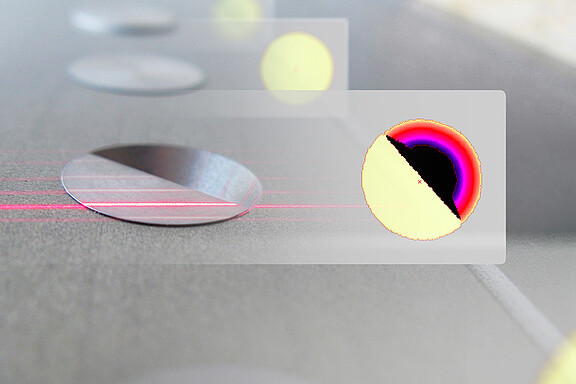

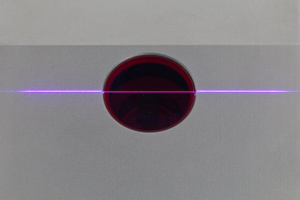

Thickness measurement on glass elements

- Depending on the sort of the glass it can be measured with blue or red scanner (depending on the surface)

- By means of the special scanCONTROL algorithms the correct reflection can be detected

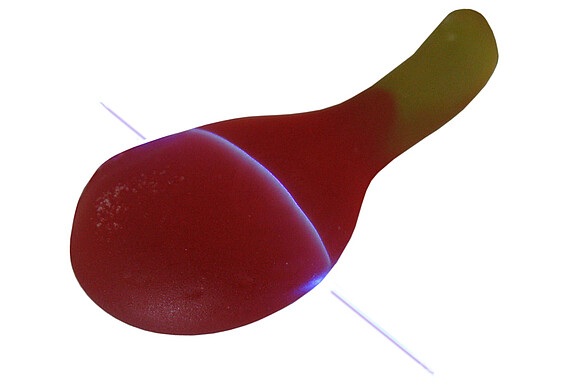

Joining gap at glued optical glasses

- The blue laser light does not diffuse into the red glass

- Gap width from 0.3 to 1 mm

- The material change from metal to glass does not cause problems in this case

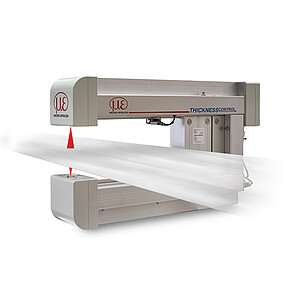

Surface control of adhesive foils

- Foil width up to 1 m

- Detection of pleats and deepenings

- The measurement works with one single traversing scanner, as every defect that appears is continued on the full length

Control of transparent glue beads

- The blue laser light does not diffuse into the material as much as the red light

- Scanning of the conture by means of a roboter arm

- Control of the completeness and detection of blurred parts

Adhesive bead measurement

- Measurement of the adhesive bead in a rubber groove

- Monitoring of the bead height

- Monitoring of the bead width

Control of stampings on leather

- Control of the correct depth of stamping

- Optical character recognition (OCR) by customers software to recognize e.g. serial numbers, part numbers, automatically.

Profile measurement on shingles

- Control of dimensional accuracy

- Shiny surfaces

- Measurement on different positions by switching the scanning parameters directly on the scanCONTROL

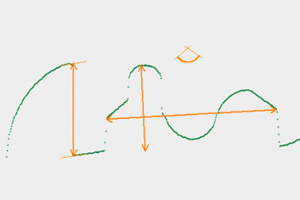

Measurement of edges on foam material

- Measurement of angles

- Uneven dark surface

- Averaging above several points to get a solid signal

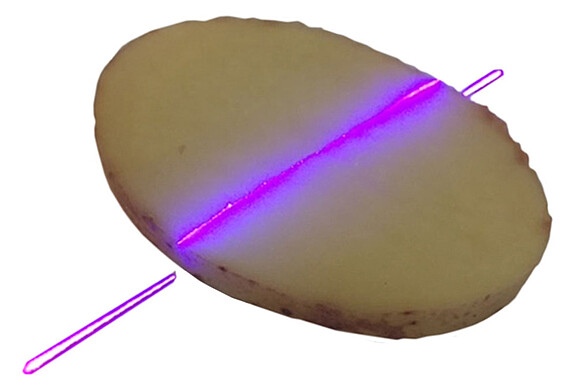

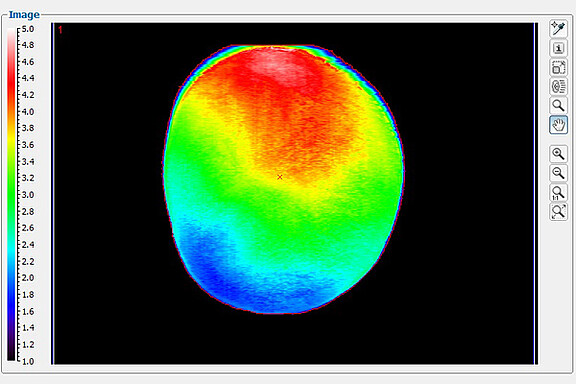

Volume control on a potato slice

- To small slices are separated out

- The limits for minimal and maximal thickness are observed

- For quality control because of continuous baking times